The second wave of coronavirus has hit the country hard. With India witnessing a massive spike in COVID-19 patients admitted in the hospitals needing medical oxygen for survival, we endure a severe health crisis as there is a shortage of medical oxygen and an inadequate supply chain. Big or small, hospitals are undergoing a tough time in arranging an adequate amount of oxygen supply to meet this special requirement in patient care. The government, private entities, and people are bending over backward to overcome this catastrophic situation. DRDO’s decision of earmarking On-Board Oxygen Generation System (OBOGS) used in Tejas Light Combat Aircraft (LCA) for civilian use and coronavirus duty is an innovative case in point today.

As we are acquiring oxygen cylinders from factories in India and across the globe, the chances of repeated handling are respectively high. Considering the current scenario this process may inflate the risk of contaminating the cylinders which can make the situation even more complex. The sanitization protocols issued by the government and several other conditions are further disrupting the on-time delivery of oxygen cylinders, giving rise to impediments such as unavailability of oxygen, increase in the price, and so forth.

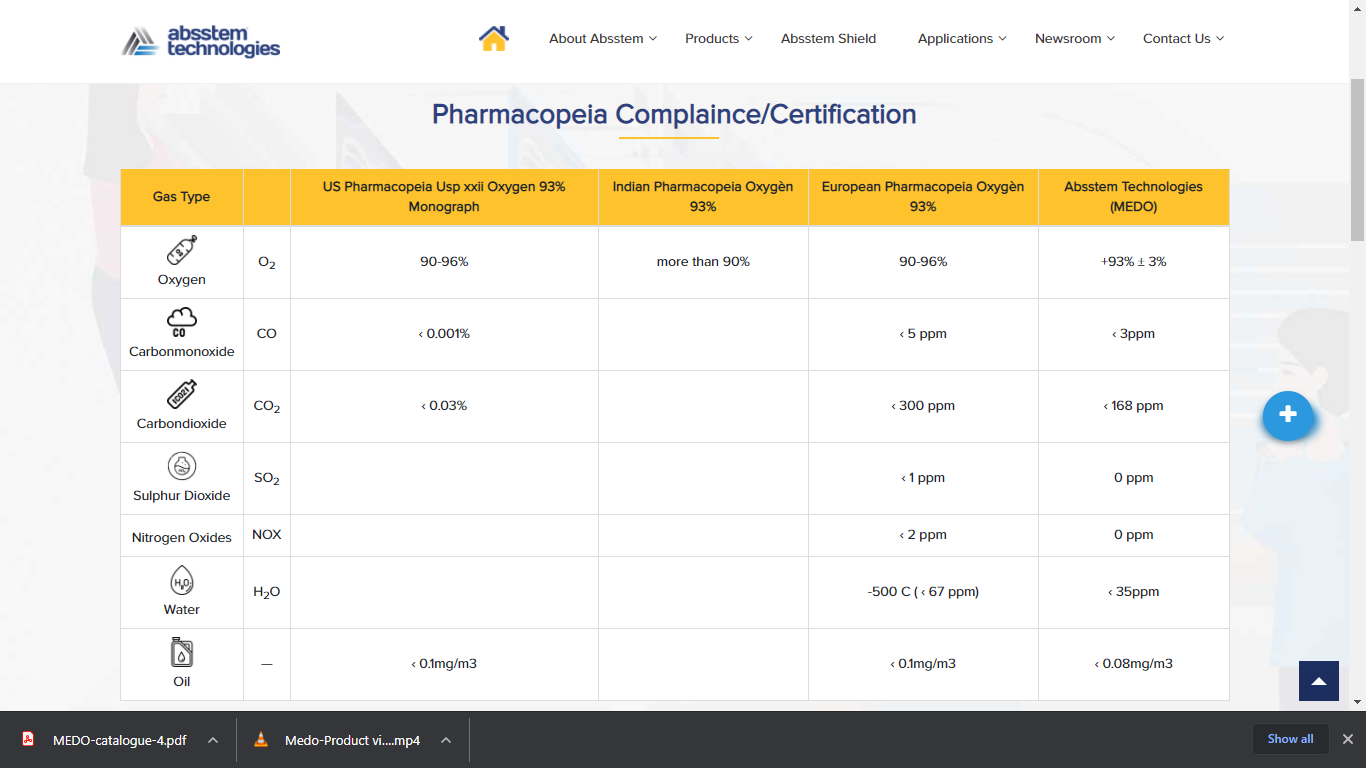

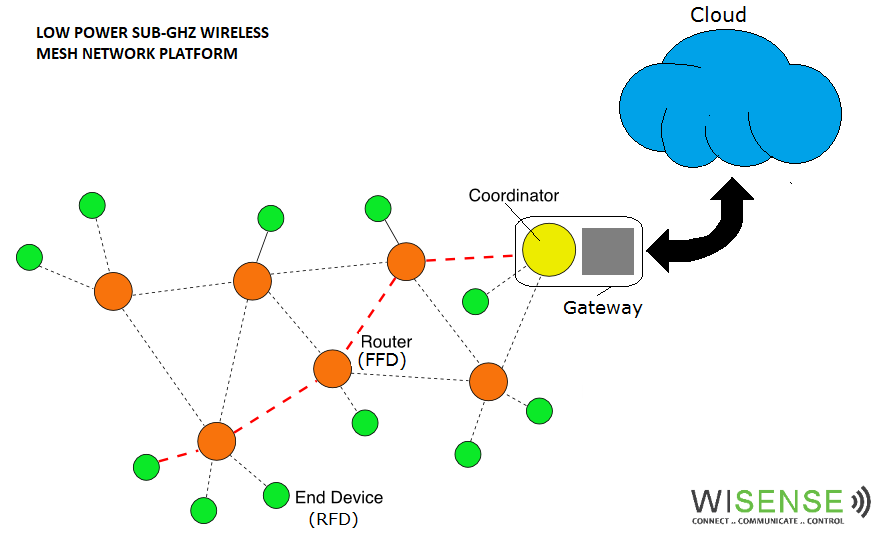

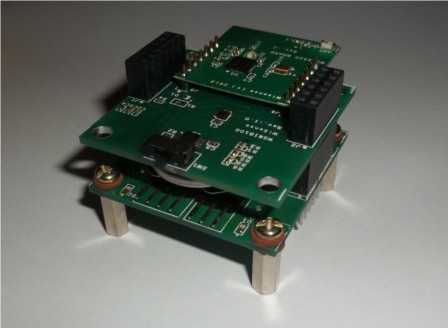

Absstem Technologies’ PSA-based disruptive solution-Medical Oxygen Generator-MedO surfaces as the savior which is capable of measuring up the sudden surge in the demand for oxygen in the country. This onsite Medical oxygen solution’s unique and high-tech features can generate medical oxygen instantly at the hospital site. It is affordable, convenient, reliable, safe generates oxygen 24/7, and requires minimum maintenance.

This Delhi-based startup, led by Mohit Sharma has to date executed over 18 deployments in different hospitals in India and across the world. Today, the team is putting their brains together to help hospitals be self-reliant by having an uninterrupted and continuous supply of oxygen.