NASSCOM Center of Excellence IoT has launched its flagship initiative in manufacturing titled The Forum for Manufacturing, Automation, Digital Transformation & Innovation Excellence (MADE), which will explore the intersection of innovation & technology in manufacturing and how this can aid the next wave of digital transformation.

At the Digital Transformation & Supply Chain- Inflection Summit & Awards 2019 held in Mumbai recently, strategies for transformation of functions in the disruptive business environment were discussed at length. Industry thought leaders representing pharma, automotive, logistics, retail, FMCG and service providers gathered to share their best practices, celebrate successful innovations and understand futuristic trends at Inflection.

NASSCOM CoEIoT-DSAI participated in two meetings – a Panel Discussion on Game Changing Trends in Automotive Supply Chain – Fuel to Future and the second, a closed group roundtable with industry leaders on Opportunities & Impediments to Accelerate Digital Transformation in Supply Chain Ecosystem within Indian industry, led by Jayen Desai, Lead – Digital Transformation, Industry 4.0 for NASSCOM CoEIoT-DSAI.

Key Inflections for the industry

The EV revolution in India is waiting to happen, and changes being witnessed at the industry and policy level indicate the next wave of environment-friendly transport. The newly-elected government is supposedly deliberating means to establish a robust EV infrastructure. The Indian EV market is poised to reach an excess of $700mn by 2025, and government schemes are expected to provide a fillip.

Secondary data from McKinsey, Deloitte and PwC indicate some interesting trends:

- One in 10 cars by 2030 will be shared vehicle

- City type will replace country/region as key parameter for sales segmentation

- Vehicle unit sales will grow ~2% annually but will be highly customized to fleet operators

- 15% of new cars sold in 2030 will be fully autonomous

During the roundtable, a conscious move from internal combustion to EV to Autonomous vehicles was recommended. Already, there is a significant change in the mindset of GenYfrom Ownership to User-ship, which exacerbates the relevance of an eco-friendly vehicle.

In addition to capitalising on a cost-effective and eco-friendly model, major disruptions in the future dealer model with OEMs can be expected mainly due to the expansive role played by technologies such as AI and the power of real-time data analytics. Additionally, Potential disruption in auto supply chain with wider adoption of 3D printed spare parts closer to point of use builds a stronger case for digital transformation.

Collaboration, Innovation and Solution Providers: An Unstoppable Combination for the Industry of the Future

The industry stands at an inflection point today. With reams of data on user preferences and climate parameters, now is the time for greater collaboration between manufacturing companies and digital technology providers. The abundance of data has also provided a bank of industry-relevant use cases, which can be leveraged with appropriate solution providers. This encourages digital transformation teams to look beyond the ecosystem.

The findings of this roundtable set the precedent for NASSCOM CoEIoT-DSAI’s newly- launched flagship industry-driven initiative called MADE – the Forum for Manufacturing, Automation, Digital Transformation & Innovation Excellence.

Key Takeaways

- There is significant work happening in the industry around supply chain automation and ecosystem.

- Most companies are taking end to end approach when it comes to industry 4.0 vs piece meal.

- A lot of focus right now on getting demand forecasting and last mile delivery when it comes to innovation in supply chain.

- Retail moving from stocking to more mass customization and just in time delivery models and this is going to be disruptive with tremendous opportunities for supply chain innovation.

- There are lot of opportunity within retail for having roadmaps for data integration and visualization to get maximum benefit for real time feedback.

- Within Pharma industry there are significant challenges in cold chain, storage, logistics, trace and track, counterfeits and this is both for domestic and international trade. Technology adoption and working at a national platform level would be highly beneficial and again this is something the COE – IOT/AI can work with the eco-system partners.

If you are an enterprise or startup keen to participate in MADE, contact Jayen Desai (t-jayen@mail.nasscom.in)

Make way for the new era of digital transformation in manufacturing

Related posts

Exclusive: Former Snapdeal exec Anand Chandrasekaran backs Uncanny Vision

Oh Baby! Deep Technology Learns To Rock

Universal Healthcare- Digital Propulsion 30th April 2019 at Shangri La’s Eros Hotel- Delhi

Your Local APMC-Mandi Just Got Smarter

Avanijal’s app irrigates fields while helping farmers save water and sleep!

Cardiotrack partners with Columbia Asia Hospitals to provide AI-based solutions in cardiac care

What Lies Ahead For India’s High-Potential Clinical Trial Market?

Say hello to #LHIF

Qualcomm Announces Top Eight Finalists for Cycle I of Qualcomm Design in India Challenge II

Hardware startup Sensegiz catches fancy of KARSEMVEN, raises $500,000

4 Bengaluru startups will work with Airbus to shape the future of aerospace

From Womb To Cloud: This Startup Is Monitoring Maternal Health Using Smart Wearables

Nestle picks up SilverPush and IotPot for its ‘next big project’

IoT India Congress recognises top three IoT focussed thought leaders and Start-up in India

The Evolution of Bluetooth: From Entertainment To Smart Buildings

Here comes the Robot Reaper

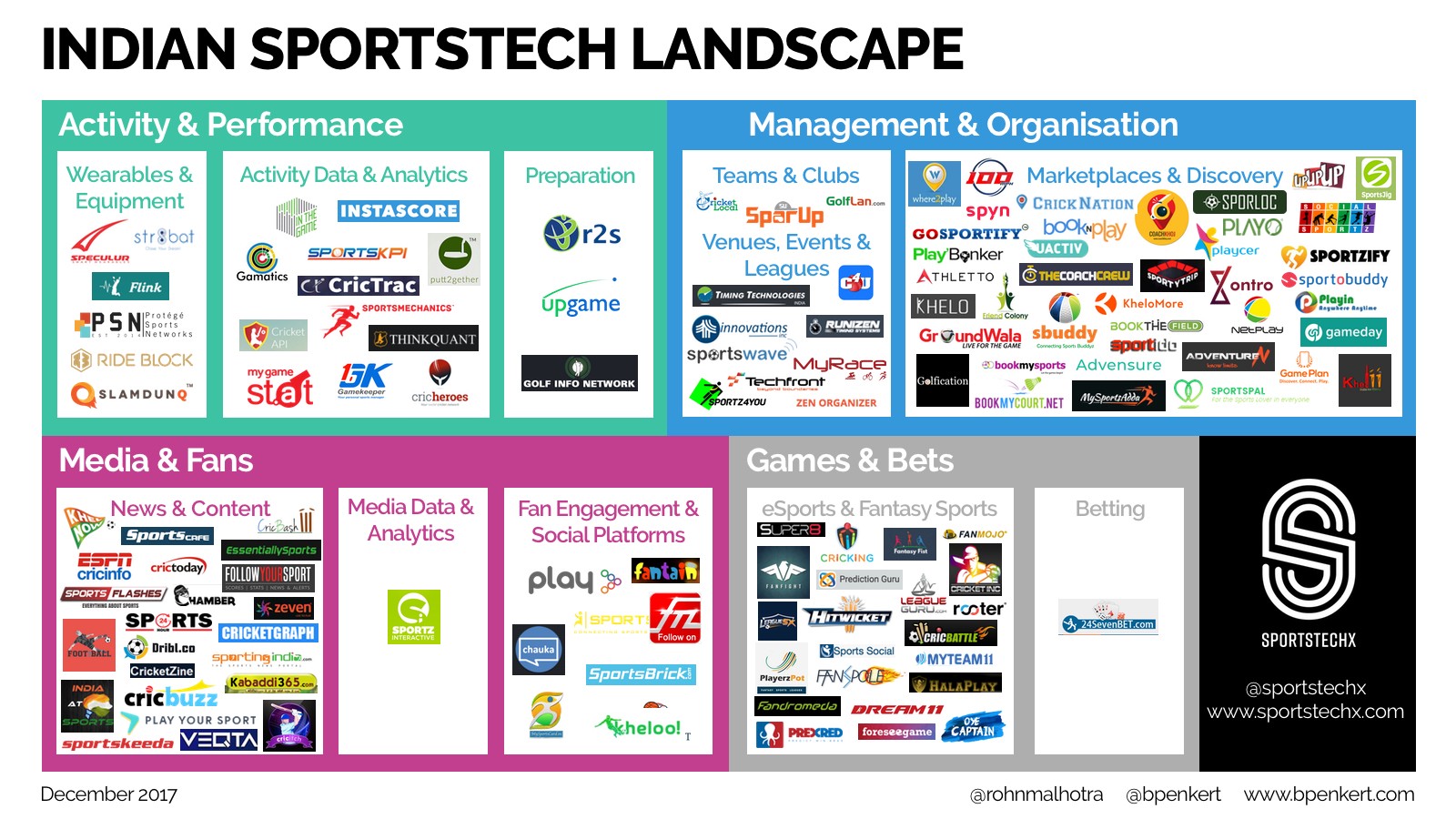

Overview of the Indian #sportstech landscape

This Bengaluru techie-turned-farmer has made India’s first agri-tech robot to battle farm labour shortage

Cardiotrack collaborates with iMMi Life for cardiac care

Villgro funds agri start-up GRoboMac

Driving Digital Awakening Across Enterprises Today

AI for an Eye Makes The World Better For The Visually Impaired

This IoT startup plugs holes in your leaky bucket

Working In Hazardous Conditions? Worry not, IoT Comes To The Rescue

BFSI – Strategy Innovation Group (BFSI-SIG)

Qualcomm selects three startups for $100K design prize

Get Set, Co-Create: This Startup Is On The Fast Lane To Innovate With Mercedes’ Startup Autobahn

Baby Steps Towards A Better Future

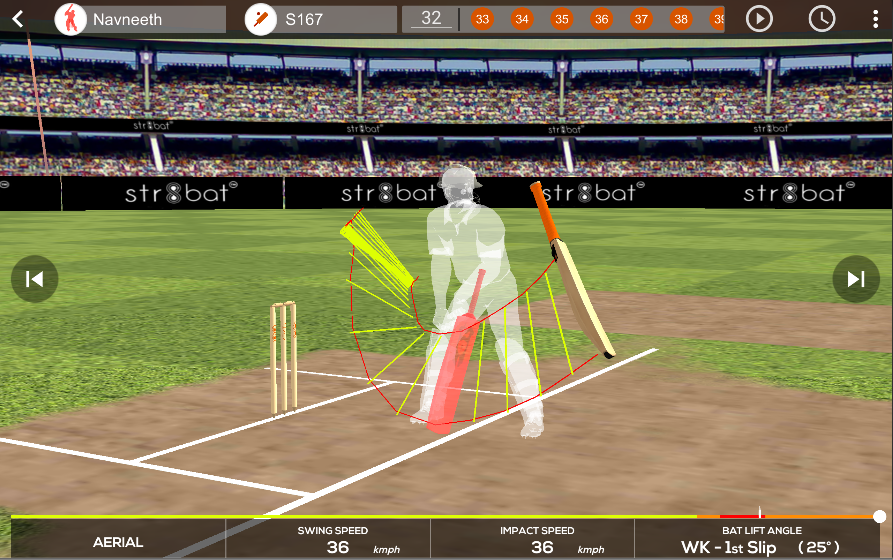

STR8BAT gives INSTANT, VISUAL and ACTIONABLE IN-SIGHTS, HELPING PLAYERS PLAY BETTER EVERYDAY

Projecting revenues of $250K, Cardiotrack is transforming how primary healthcare functions

LHIF Report Nov 2018

When All Else Fails, This Internet Network Can Bail You Out Of A Crisis

Medtech takes centre stage at AIRmaker’s new batch of 8 IoT startups

IoT Pot plans to take cooking Knob to US

Data-driven insights for an improved game on the cricket field

IoT industry should have common standards: Teaotia

GE Healthcare India Edison[TM] Accelerator: The first-ever global startup collaboration program!

Reliance’s Unlimit, IBM collaborate to power IoT innovation in India

A Billion Dollar Market – India’s Health Insurance Market Is At A Precipice Of Change

Here Are 3 Startups From India You’ll Want To Watch In 2017

SenseGiz-A vision to make the world appreciably productive, safer and secure place to live in!

Qualcomm to announce tech startup winners of $100,000 Design in India challenge today

Transforming Sports Gear into Smart Devices to Deliver Real-Time Analytics

Portable ECG device helps save lives in rural areas, reduces cost for patients

SeeHow Announces Smart Cricket Coaching System in Partnership with Rx Cricket Academy

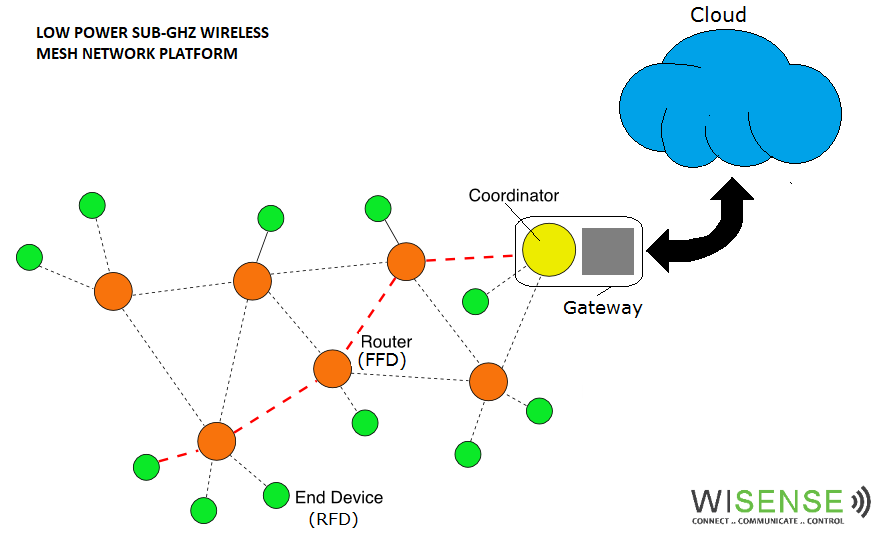

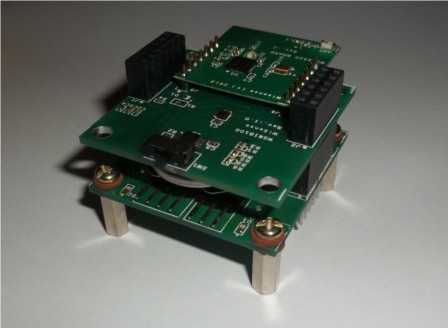

WiSense: engineering veterans provide a platform for Internet of Things ideas

Nasscom Discussion

Latest News

Recent Posts

- From Industries to Public Services: AI Innovation Challenge Bridges Tech and Real-World Impact July 10, 2025

- The Future of Incubation: What the Next Generation of Startup Support Looks Like April 29, 2025

- The Impact of AI in Healthcare April 22, 2025

- The Evolution of AI & Industry 4.0 – What’s Next? March 26, 2025

- Disrupting Supply Chain Management: Meet Startups Driving Innovation March 17, 2025