The wide adoption of industry 4.0 technologies has transformed the fundamental processes in the warehouse, logistics, and manufacturing sectors. Advanced technology such as the Autonomous Mobile Robot (AMR) has narrowed the gap between humans and machines and assisted in overcoming upfront industry challenges like lack of skilled labor, excessive labor cost, improper management & substandard process, instability in the supply chain, and so forth.

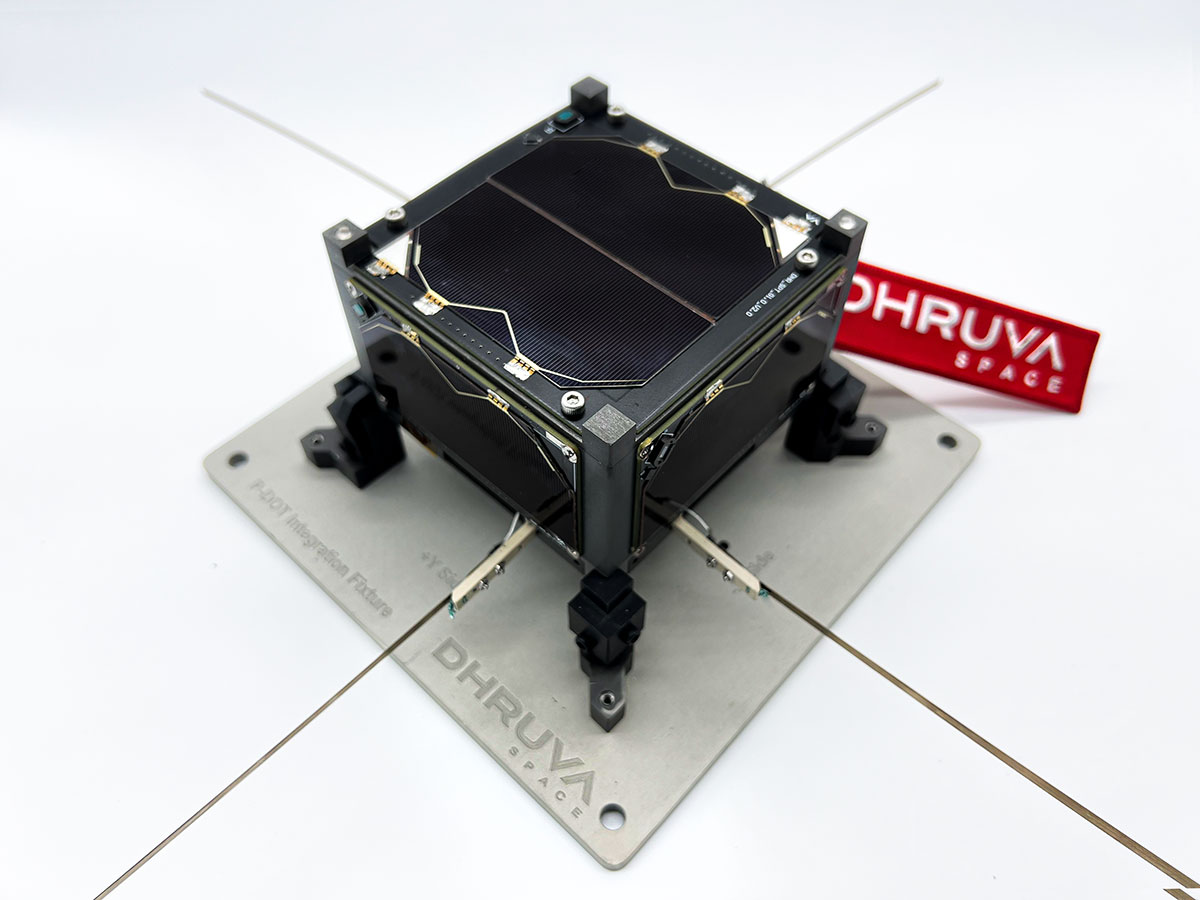

Four Nanyang Technological University (Singapore) alumni and passionate robotic enthusiasts, Singaram Venkatachalam, Prashant Trivedi, Nikhil Venkatesh, and Rahul Nambiar, banded together to home in innovative automation solutions that spur the advances and adoption of Industry 4. 0. They founded Botsync in 2017 with the vision of making manufacturing, warehousing, and logistics daily material movement operations smart and agile. The team synced up mobility & robotics to devise safe, pragmatic, easily deployable, and accessible heavy-duty MAG Autonomous Mobile Robot (AMRs) solutions to help organizations to automate intralogistics operations as per their needs. The aim is to empower organizations to improve flexibility, productivity, agility, and efficiency of their day-to-day intralogistics operations.

Botsync was incubated at Center of Excellence, Bengaluru, which is a Joint initiative of the Ministry of Electronics and Information Technology (MeitY), Govt. of Karnataka, and NASSCOM.

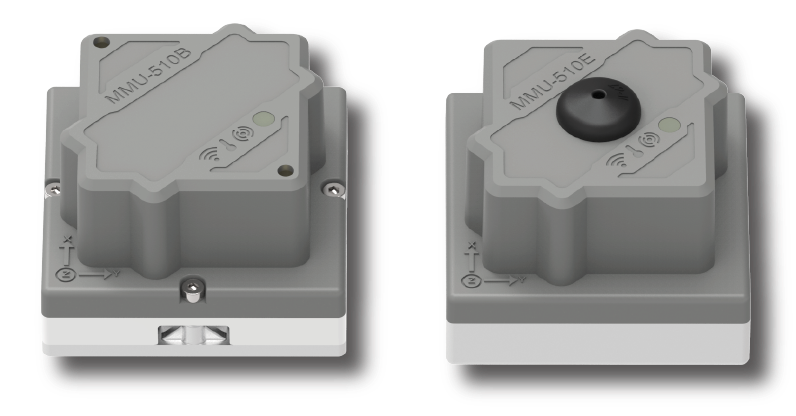

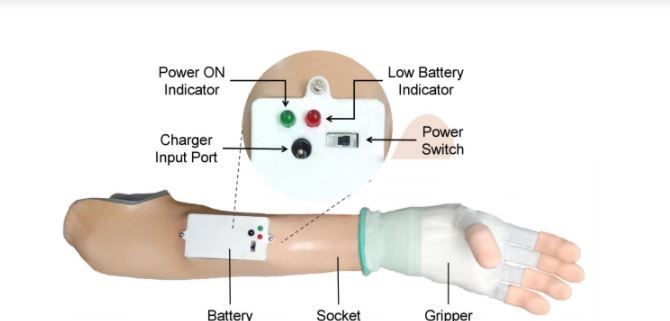

Bringing together the proficiency and industry know-how, Botsync designed its key product MAG AMR-a fleet of intelligent autonomous mobile robots (AMR), which automates intralogistics operations and movement of bulky commodities from 300 kilograms to 2200 kilograms around the warehouses and factories. The robot is available in two distinct models: MAG300 AMR & MAG1000 AMR, which comes with swappable top application modules that can change it functionality to pallet lifter, pallet conveyor, trolley tugger, and trolley lifter. The team also created a unique software system called the syncOS to amplify operations with advanced automation. The system is composed of integrated building blocks automation whose configuration can be reordered effortlessly into solutions as per task specifications. Some of its key features include Workflow Creator, Robot Configure, Fleet Manager, 3rd Party Integrator, Throughput Simulator, And A Human Machine Interface.

Botsync’s vocation quickly garnered the attention of industry leaders and is being supported by leading investors like Venture Catalysts, Angle Central, Artesian, Brinc, Wong Fong, ZB Capital, SEEDS Capital and many more. Up to now, the startup has deployed its solution and served many renowned organizations across verticals such as automotive manufacturing, FMCG manufacturing, 3PL warehouses, electronics and textiles in India, Thailand, and Singapore. This testifies to the startup’s journey of how it has bloomed since its inception. It has burst forth in terms of its geographical presence, having set offices in Singapore and Bengaluru. At the time of initiation, the startup had a team of 15 members, which has today grown to over 35. Their advisory board compromises thought leaders from the logistics, manufacturing, robotics, and startup sectors, who impart their knowledge and experience to mentor the team on its technical development and business strategies.