India’s manufacturing capabilities are growing from strength to strength every year. In recent times, the impressive growth of the manufacturing sector can be credited to the application of technology like IoT.

Combining advanced manufacturing processes and technology offerings had led to the promise of a truly revolutionary era in industrialization – Industry 4.0. Companies are investing in technology that make operations smarter, intuitive and responsive. This is the power of the Internet of Things (IoT), which is eliminating challenges pertaining to manufacturing inefficiencies, and changing the relationship dynamic between man and machine.

One of the most influential trends that will shape the course of Industry 4.0 is the Industrial Internet of Things (IIoT)1. More devices will be enriched with embedded computing, allowing them to interact and communicate with each other better.

Already, organizations are seeing the impact of IoT on their businesses. According to Forbes Insights2, 45% of executives report that IoT has boosted profits by 5% while 41% claim that the impact of IoT has enhanced revenues by 15% annually.

IoT ensuring worker safety in industries

The extensive usage of wireless communications, Internet, innovative solutions, predictive maintenance has allowed Manufacturing Execution Systems to further the cause of digital transformation of the industry. One of the most significant influences seen in recent times is of IoT’s role in enhancing worker safety in the industrial sector. It can get tedious to monitor the safety and working conditions of thousands of workers in a factory or a manufacturing unit, but one misstep can lead to losses amounting to millions. This is where IoT comes in.

Some examples of IoT-enabled solutions for worker safety include:

- A cognitive wearable technology can help improve employee’ safety in dangerous environments – such as during operation of massive machinery, exposures to extreme heat or toxic gases, open flames, open risky spots etc. The sensors can monitor the location of the worker, the working style in terms of bending, lifting, handling of equipment and much more by gathering and analysing data collected from sensors embedded in helmets and wrist bands etc. Such a technology can provide real-time alerts to employees and their managers, enabling preventive measures if physical well-being is compromised or safety procedures have not been accounted for.

- Analysis of data collected from various sensors that constantly monitor the worker’s location, body temperature, heart rate, galvanic skin response and level of activity can help provide a feed back to supervisor for intervention when required. This can help increase awareness of stress, exertion, warning of accident prone areas, injuries. A solid foundation therefore can be built for increasing worker safety by creating a feedback loop monitoring the environment around the worker at the workplace.

- With edge computing, data storage can be controlled and cognitive IoT would help analyse the data from employees, equipment and the facilities for allowing managers to identify potential risks and trouble spots, prevent risky behaviour of employees and avert accidents and injuries. This in turn would create a tremendous impact on the total cost for workers’ compensation and insurance for facilities at the same time.

IoT in India a Multi-Billion Dollar Market

Until a few years ago, IoT was considered an exciting but niche domain in the technology space. It almost always begged the question – does one really need it at home, in office or in a factory? The answer today is most definitely yes.

NASSCOM estimates that the Indian IoT market toreach $15bn by 2020, and the global market will grow by $3 trillion. Consumer and industrial applications are expected to drive IoT growth, with sectors like manufacturing, logistics, automotive and transportation expected to enable the growth of IoT in India.

NASSCOM’s Center of Excellence for IoT is yet another example of developing a strong deep tech ecosystem in India, specifically in emerging technologies like IoT. Experts believe that the time is ripe for startups to tackle ground-level challenges in IoT, especially in the B2B sector.

And these measures have propelled the growth of IoT-based startups in India. There are around 1,250 startups in India, most of them concentrated in Bangalore, followed by NCR and Mumbai. There has been a tenfold increase in the number of IoTstartups since 2015, largely as a result of the support from technology and manufacturing companies.

The future looks bright for India’s innovators, and the support of corporates and the government alike can propel the innovation curve in India significantly.

Related posts

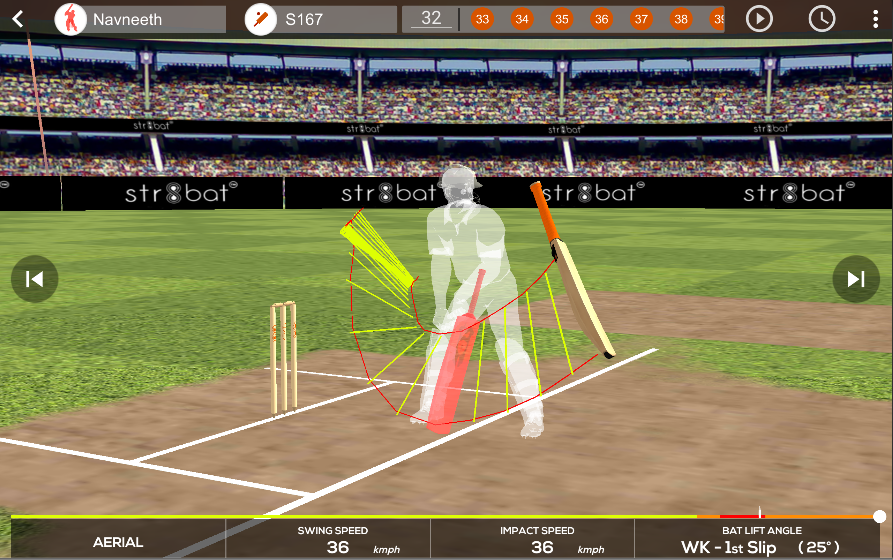

STR8BAT gives INSTANT, VISUAL and ACTIONABLE IN-SIGHTS, HELPING PLAYERS PLAY BETTER EVERYDAY

Cardiotrack partners with Columbia Asia Hospitals to provide AI-based solutions in cardiac care

Driving Digital Awakening Across Enterprises Today

Portable ECG device helps save lives in rural areas, reduces cost for patients

Universal Healthcare- Digital Propulsion 30th April 2019 at Shangri La’s Eros Hotel- Delhi

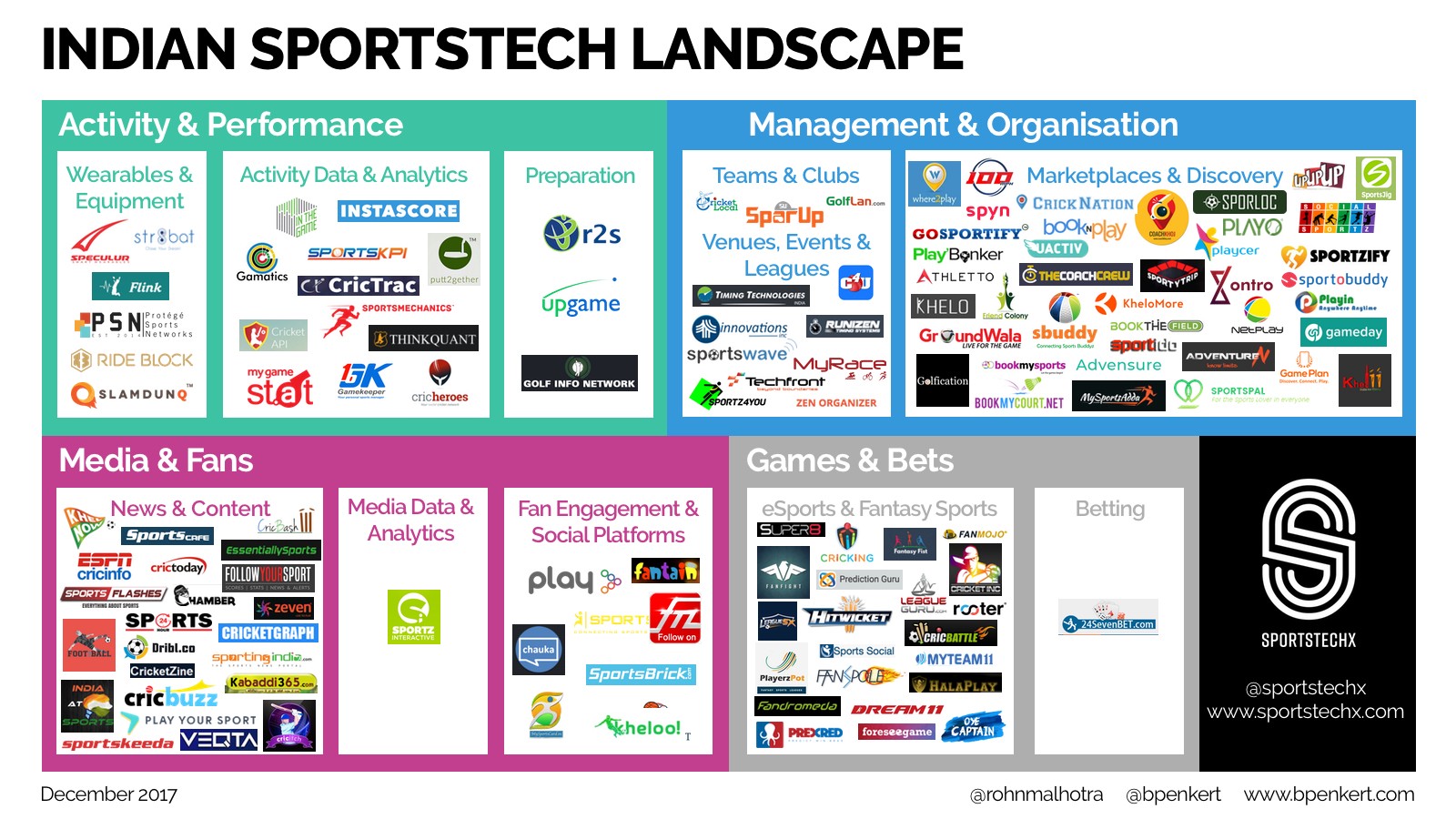

Overview of the Indian #sportstech landscape

Data-driven insights for an improved game on the cricket field

Here Are 3 Startups From India You’ll Want To Watch In 2017

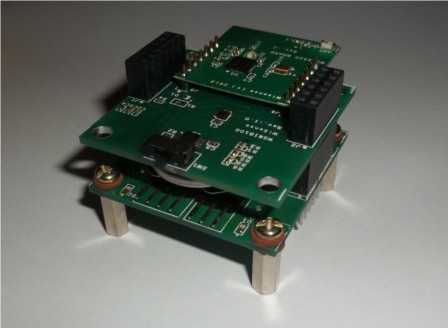

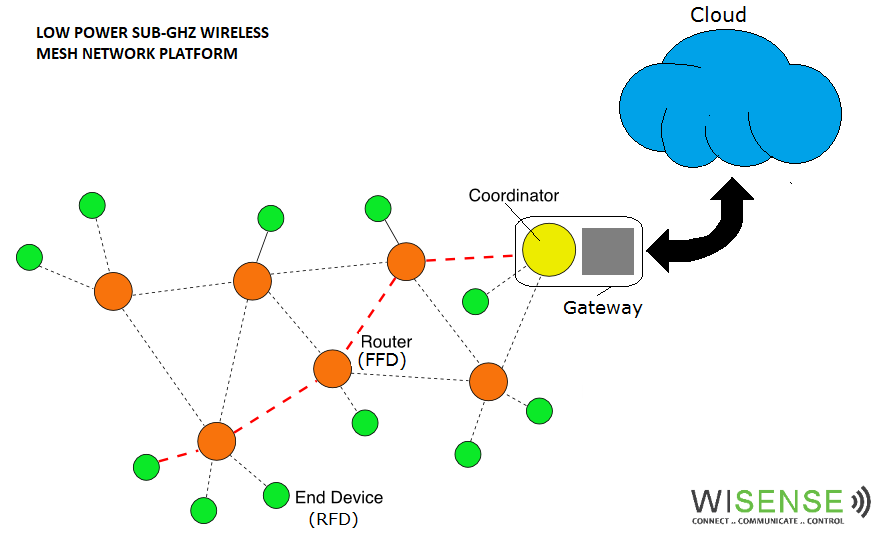

WiSense: engineering veterans provide a platform for Internet of Things ideas

The Evolution of Bluetooth: From Entertainment To Smart Buildings

Medtech takes centre stage at AIRmaker’s new batch of 8 IoT startups

Cardiotrack collaborates with iMMi Life for cardiac care

Transforming Sports Gear into Smart Devices to Deliver Real-Time Analytics

GE Healthcare India Edison[TM] Accelerator: The first-ever global startup collaboration program!

Here comes the Robot Reaper

From Womb To Cloud: This Startup Is Monitoring Maternal Health Using Smart Wearables

Oh Baby! Deep Technology Learns To Rock

What Lies Ahead For India’s High-Potential Clinical Trial Market?

Qualcomm selects three startups for $100K design prize

Exclusive: Former Snapdeal exec Anand Chandrasekaran backs Uncanny Vision

This Bengaluru techie-turned-farmer has made India’s first agri-tech robot to battle farm labour shortage

How Industries & Innovators Can Leverage The Power of Digital Technology in Manufacturing

Qualcomm Announces Top Eight Finalists for Cycle I of Qualcomm Design in India Challenge II

LHIF Report Nov 2018

Avanijal’s app irrigates fields while helping farmers save water and sleep!

SenseGiz-A vision to make the world appreciably productive, safer and secure place to live in!

Villgro funds agri start-up GRoboMac

Say hello to #LHIF

IoT Pot plans to take cooking Knob to US

4 Bengaluru startups will work with Airbus to shape the future of aerospace

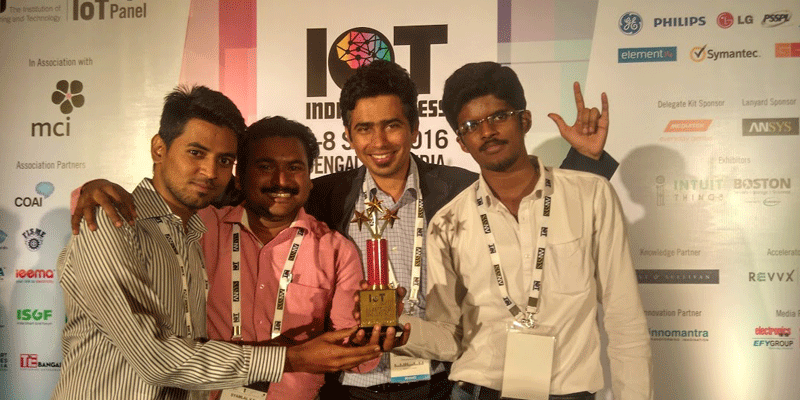

IoT India Congress recognises top three IoT focussed thought leaders and Start-up in India

This IoT startup plugs holes in your leaky bucket

Reliance’s Unlimit, IBM collaborate to power IoT innovation in India

Your Local APMC-Mandi Just Got Smarter

Qualcomm to announce tech startup winners of $100,000 Design in India challenge today

Baby Steps Towards A Better Future

IoT industry should have common standards: Teaotia

Hardware startup Sensegiz catches fancy of KARSEMVEN, raises $500,000

Projecting revenues of $250K, Cardiotrack is transforming how primary healthcare functions

AI for an Eye Makes The World Better For The Visually Impaired

SeeHow Announces Smart Cricket Coaching System in Partnership with Rx Cricket Academy

A Billion Dollar Market – India’s Health Insurance Market Is At A Precipice Of Change

Nestle picks up SilverPush and IotPot for its ‘next big project’

BFSI – Strategy Innovation Group (BFSI-SIG)

When All Else Fails, This Internet Network Can Bail You Out Of A Crisis

Get Set, Co-Create: This Startup Is On The Fast Lane To Innovate With Mercedes’ Startup Autobahn

Nasscom Discussion

Latest News

Recent Posts

- From Industries to Public Services: AI Innovation Challenge Bridges Tech and Real-World Impact July 10, 2025

- The Future of Incubation: What the Next Generation of Startup Support Looks Like April 29, 2025

- The Impact of AI in Healthcare April 22, 2025

- The Evolution of AI & Industry 4.0 – What’s Next? March 26, 2025

- Disrupting Supply Chain Management: Meet Startups Driving Innovation March 17, 2025