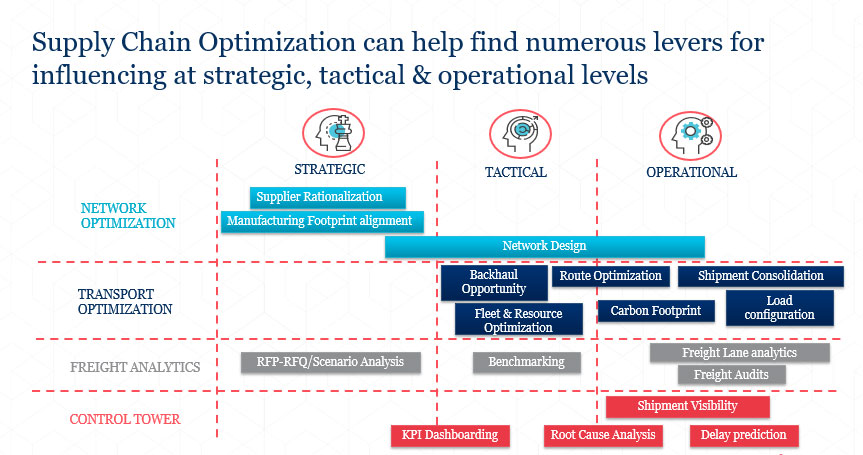

As COVID-19 continues to impact business dynamics, supply chains are still facing disruption. Organizations using old legacy systems and processes are finding it hard to adapt to the new realities. And longer-term supply chain strategies, such as network optimization, need to be reassessed to increase agility.

Although supply chain network optimization covers the end-to-end function, I’m going to focus on the logistics network as a starter as it’s one of the critical streams of SC optimization and brings in clear use cases to optimize costs.

Supply chain network optimization is typically carried out only occasionally and usually as a precursor to a major change of network entities e.g. bringing in a new supplier base, changing manufacturing locations, or changing the distribution footprint. Often, these changes are led by an outside consultant, and strategy recommendations are left to the organization to implement.

Transportation network optimization is either outsourced to a third-party or done as part of a transport management system (TMS) set-up configuration as a one-off activity.

Carrier analytics, another major pillar in framework optimization, is a core activity and is carried out in most organizations, evaluating historical performance using key parameters to guide future strategy. However, this is still a manual exercise in MS Excel for most the firms.

You’ll also find business impact and visualization for activities spread across multiple reports with backward-looking descriptive analytics; making it difficult to take proactive actions.