| Industry | Usecase Description | Turnover |

|---|---|---|

| Electro Mechanica Assemblies Manufacturer i.e. wiring harness, PCB assembly, wiring harness etc. | Usecase - 1 : The manufacturing data needs to be e-logged across operators and machinery so that we get decisive information to improve our manufacturing processes for efficiency and effectiveness. The data should give me the WIP status across projects, help the Organisation to effectively plan production activities. | 5-50 Cr. |

| Safety Equipment Manufacturer | Usecase - 2 : Camera based quality inspection for our FRP tubes (typical length is more that 5ft and may go up to 19 ft – It Should use AI powered camera to inspect the quality / defects and automate the inspection process. It can be fitted along with production line i.e. conveyer belts for rapid inspections. As we need to have ASTM D3299 Standard Specification such as, UV Curature, Surface texture , alignments, Filament-Wound Glass-Fiber-Reinforced Thermoset Resin Corrosion-Resistant & Anti-bucking properties. The company is also planning for Engineering safety Polycarbonate Googles in next couple of months and exploring automated solutions for QC in that project also. (Vision based or AI based UTRA testing for its complete range of GOOGLES) | 5-50 Cr. |

| Engineering | Usecase - 3 : To digitalize our production process, we propose an app that tracks key data from workers, including their name, the machine and part they’re working on, and daily output. This data will be compared to baseline metrics like setup and production times to measure efficiency. Supervisors can monitor performance in real-time and identify bottlenecks, while managers can track order progress and generate reports. The app will send alerts for delays and allow workers to log downtime or maintenance issues. Real-time insights will help optimize workflows, improve decision-making, and drive continuous improvement in productivity. | 0-5 Cr. |

| Food Processing | Usecase - 4 : The company is specializing in manufacturing fish products, including fish meal, fish oil and fish soluble paste, which are primarily supplied to pharmaceutical, animal feed, fish feed companies, etc. The company’s operations depend on two processing lines and a boiler, and the availability of raw materials, such as fish, is seasonal, which makes peak-season efficiency critical for the company. The company is seeking a solution that can Monitor key parameters such as yield of fish products, operator availability, and machine performance in real-time. Provide actionable insights and generate alerts in case of anomalies to enable timely corrective actions. This will help companies to ensure maximize operational efficiency during peak seasons. | 5-50 Cr. |

| Food Processing | Usecase - 5 : A Wheat Flour Mill specialized in producing wheat flour products such as maida, atta, suji, bran, chakki atta, and all-purpose flour. These products are primarily supplied to wholesalers, bakeries, and similar establishments. The current operations are entirely manual, relying on Excel sheets and Business WhatsApp for day-to-day tasks. Orders are received through Business WhatsApp and then manually recorded in Excel sheets. This data is used to manage production, inventory, and procurement. Once production is completed, the packaging is done as per order requirements. The entire process is manual, making it challenging to ensure data accuracy, timely decision-making, and operational efficiency. To overcome these challenges, there is a need to digitalize the processes, integrate various departments, and ensure that data is easily accessible and actionable.

The manufacturer seeks a cost-effective digital solution to replace manual processes. The solution should enable seamless integration of order management, production, inventory, and packaging operations while providing tools to monitor and manage data effectively. It should generate alerts to identify anomalies so that timely corrective actions can be taken. A cloud-based system, preferably on platforms such as G-Suite, is desired to ensure scalability and ease of access. Additionally, a proven track record of implementation in similar industries, such as flour mills, would be a significant advantage. The overarching goal is to maximize operational efficiency, ensure accurate data handling, and improve decision-making processes. |

50-100 Cr. |

| Engineering | Usecase - 6 : Engineering Company specializes in manufacturing assembled & individual components for the electrical industry. We're facing challenges in tracking inventory at different workstations. Accurate monitoring of raw materials, work-in-progress (WIP), and finished parts are critical to maintain the required stock and track the operational efficiency. Currently the records are being kept manually. We want to digitize the data of inventory either using QR Code / Barcode / RFID based solutions or Elogbook solutions. A centralized dashboard should provide real-time updates on inventory levels, WIP, and finished goods. It will also simplify inventory counting, enhance operational transparency, and ensure timely availability of materials for uninterrupted production. | 0-5 Cr. |

| Food Processing | Usecase - 7 : The company is a leading Rice processing plant, with fully automated milling facility of Satake machinery - the company owns ISO, GMP, HACCP certifications and licenses to export the rice to foreign markets. The company is currently using basic PLC and SCADA systems to keep track of the machine and its operations. The company seeks to digitalize its other operational processes and keep track of CCP ( Critical Control Points ) such as broken rice percentage, moisture check for operators. Inward outward movement for supervisors. Raw material and final product quality check for technicians, stock updates. e-Gatepass approvals ( similar to myGate app ). To address this, an E-logbook based system is desired to digitalize paper based records. The system will also help in realtime monitoring of critical parameters so that they can be further analysed for corrective actions. A live dashboard will help for better visualization of plant performance. Along with this - there are various smart solutions available - we are very keen to implement them. | 50-100 Cr. |

| Engineering | Usecase - 8 : The company is a manufacturer of Molded Rubber Parts like Gasket, Cords, Washers, and "O" Rings etc. The company is looking to improve the traceability and Quality Control system in the plant. The company mainly owns, mixing mill , Testing facility (lab) and multiple compression molding machines. The rubber compounds (batches) processed from the mixing mill are tested in lab for matching customer specs and are then issued further to make multiple products with compression molding process. The company is looking for a Barcode / QR Code or any software-based solutions which can track from Inward of raw materials , Work-In-Progress (WIP), and Finished goods stages across the plant. In addition, It is desired to keep a record of co-relation between rubber compounds (batches) and products made from it. An interactive dashboard will give updates of key parameters such as inventory at various stages, production counts, worker details etc. at the plant. | 0-5 Cr. |

| Engineering | Usecase - 9 : The company is a leading manufacturer of industrial valves and valve components such as balls, stems, and glands, serving the Oil & Gas industry, OEMs, and occasionally end-users. Using advanced technology, the company specializes in custom ball valves with high product variations. The company faces challenges in inventory management across its manufacturing processes. Currently, a Tally-based ERP system is being used. The company seeks real-time tracking of inventory and monitoring of raw materials, work-in-progress (WIP), and finished goods. Additionally, they aim to track inventory movement across the shop floor and warehouse. The company is looking for a QR code- or barcode-based inventory management system to enable detailed tracking and real-time monitoring of components, WIP, and finished goods. Prioritizing traceability and accurate, up-to-date data, the company aims to optimize inventory control, improve process efficiency, and adapt to its custom manufacturing requirements. | 0-5 Cr. |

| Chemical | Usecase - 10 : The company is a leading provider of specialty industrial gases and related solutions. It currently manages around 2,500 cylinders that move between the filling plant, warehouse, and customer locations. The company faces challenges in identifying which cylinder has been delivered to which customer and how long it has remained with them. To address this, the company is seeking an RFID, Barcode, or QR Code solution to track and trace the cylinders. This system will integrate with the Tally ERP system to link tracking information with invoices, streamlining operations and simplifying workflows. | 0-5 Cr. |

| Electronics Component Manufacturer | Usecase - 11 : The company is facing significant challenges in managing inventory and production processes due to reliance on manual methods. These challenges include time-consuming data entry and record-keeping, lack of real-time visibility into inventory levels and production status, frequent human errors in order tracking and resource allocation, and inefficiencies in managing production schedules, leading to delays in fulfilling customer demands. To address these issues, company is seeking a robust solution that can automate repetitive tasks, reduce errors, provide real-time operational insights, and streamline workflows. Such a solution would enable to optimize resource management, enhance efficiency, and improve customer satisfaction through timely and accurate order fulfillment. | 5-50 Cr. |

| Industrial Machinery Manufacturer | Usecase - 12 : The company is a designer and manufacturer of high precision injection molds, stamping dies, machined insert, plastic, sheet metal components and sub-assemblies. The company has a large pool of capital equipment. The company wants to implement an end-to-end solution to digitalize the whole business process. Process starts from a customer enquiry receipt. Followed by Cost estimate preparation, Quote preparation, Demand Management, Project Management (NPD), Manufacturing Engineering, Production Planning, Shop floor execution, Purchase of materials and services, Quality Management, Inventory Management, Dispatch and Invoicing, Accounting & Costing. These main processes need to be supported with Human Resource Management for Attendance, Training, and Payrolls. Performance of each resource needs to be monitored in real-time. Every tool needs to be monitored for performance, life span, maintenance, and actual cost. Project Management module need to support APQP / IATF requirement. System should support preserving of all documents in digital form. Management wants to get several KPI reports on a dashboard. | 5-50 Cr. |

| Furniture Manufacturing | Usecase - 13 : The company is specialized in manufacturing furniture’s both for B2B and B2C sector. As it is highly unorganized sector, it is very difficult to grow and scale up. So, the company is looking to digitalize our processes like CRM, ERM, HR management to have higher efficiency, better quality, as well as to identify our bottle neck in the business. Company deploys manpower at different level, so having these digital systems will be helping to achieve better decision making, optimize work flow, improve our productivity, reducing wastage and grow our business efficiently. | 0-5 Cr. |

| Tyers Manufacturing | Usecase - 14 : A manufacturer of solid rubber tires seeks to improve traceability and streamline order tracking to enhance operational efficiency. Their production process, which includes raw material mixing, forming, curing, and dispatching, currently lacks a unified system to track work-in-progress (WIP) and manage orders. This creates challenges in monitoring production progress, identifying bottlenecks, and providing customers with accurate order status updates. Implementing a robust solution that integrates barcode or QR code-based tracking for raw materials, WIP, and finished goods, coupled with automated data capture, would effectively address these issues. Real-time dashboards offering updates on order status, WIP stages, production counts, and inventory levels would enable efficient monitoring and quick identification of delays. Such a system would ensure timely updates on order progress, enhancing transparency and building customer confidence. By identifying bottlenecks and optimizing workflows, it would improve planning, ensure on-time deliveries, and enhance resource management. | 5-50 Cr. |

| Engineering | Usecase - 15 : The company specializes in designing and manufacturing high-precision stamping dies, machined inserts, and sub-assemblies. The company boasts a large array of capital equipment, including machinery and tools, and employs around 30 people. The company aims to implement an end-to-end solution to digitize its entire business process, starting from the receipt of customer inquiries. This process will encompass cost estimate preparation, quote preparation, manufacturing engineering, production planning, shop floor execution, procurement of materials and services, quality management, inventory management, dispatch, and invoicing, as well as accounting and costing. Furthermore, this system needs to support Human Resource Management functions such as attendance tracking, training, and payroll processing. It should also monitor the real-time performance of each resource, including operators, tools, and machines. The system must enable the preservation of all documents in digital form. Management requires various KPI reports to be available on a dashboard. | 0-5 Cr. |

| Engineering | Usecase - 16 : The company specializes in designing and manufacturing high-precision stamping dies, machined inserts, plastic components, sheet metal components, and sub-assemblies. It boasts a large array of capital equipment, including machinery and tools, and employ around 30 people. The company aims to implement an end-to-end solution to digitalize our entire business process, starting from the receipt of customer inquiries. This process will encompass cost estimate preparation, quote preparation, manufacturing engineering, production planning, shop floor execution, procurement of materials and services, quality management, inventory management, dispatch, and invoicing, as well as accounting and costing. This system needs to support Human Resource Management functions such as attendance tracking, training, and payroll processing. | 0-5 Cr. |

| Engineering | Usecase - 17 : The company is specializing in designing and manufacturing high-precision tool, stamping dies, machined inserts, plastic and sheet metal components, and sub-assemblies. With around 50 employees, the company has a wide range of machinery, tools, and capital equipment. The company wants to implement a complete solution to streamline our business processes, starting from customer inquiries to final invoicing. This includes cost estimation, quote preparation, manufacturing engineering, production planning, procurement, shop floor execution, inventory management, quality control, dispatch, and accounting, human resources. The system should include a dashboard that provides real-time monitoring and analytics, enabling management to track daily activities. | 0-5 Cr. |

| Engineering | Usecase - 18 : The firm specializes in designing and manufacturing precision plastic injection molds, press tools, plastic components, and mold spares, with a team of 45 skilled professionals and advanced machinery. To streamline unique, non-repetitive projects, the company seeks a digital solution to track WIP, inventory, and profitability. The system should cover the entire manufacturing process, including estimation, sales, project management, production, procurement, quality control, inventory, dispatch, invoicing, and costing. It must also support HR functions and real-time monitoring of operators, tools, and machines. Additionally, tool lifespan, maintenance, and costs should be tracked, with all documents stored digitally. A centralized dashboard is essential for data-driven decisions. | 0-5 Cr. |

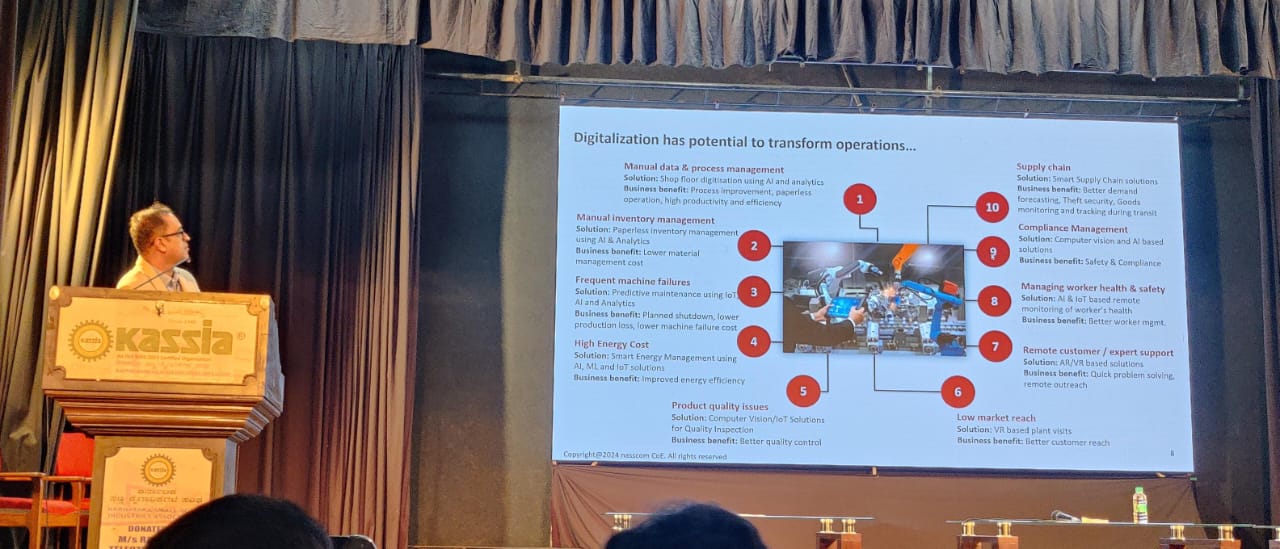

The Government of Karnataka is hosting the Global Investors Meet 2025, reflecting on the role that Karnataka is playing in promoting growth which is tech-driven, green, inclusive, and resilient.

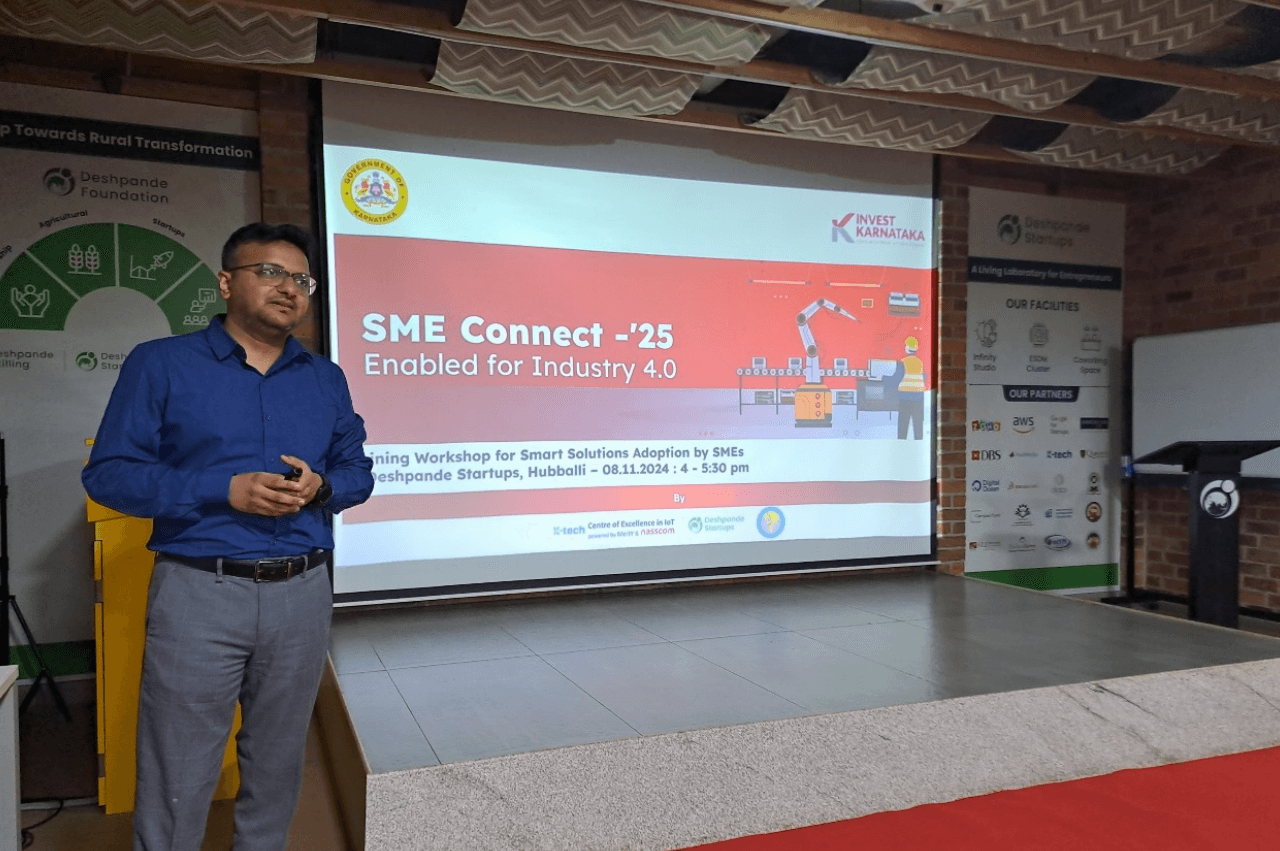

SME Connect'25 - a dynamic event which will run concurrently with the Global Investor Meet 2025, has been designed for SMEs, to enable and expand business opportunities for them through exposure, future readiness, and enablement.

To make SMEs future ready, the Govt. of Karnataka is launching SME Connect - '25 - Enabled for Industry 4.0 Program. The objective of this program is to empower SMEs by facilitating the adoption of advanced technologies, thereby enhancing their operational efficiency, product quality and making them competitive. The program aims to build their capabilities and create role models among SMEs that can inspire others in the industry to embrace technological advancements, fostering a culture of innovation and digital led industrial growth.

| Company Name | City | Company Website | Turnover | Solutions offered by the company |

|---|---|---|---|---|

| Accutech Infosystems pvt Ltd | Bengaluru | www.accutech.co.in | 100 - 250 Cr. | Machine Monitoring for Energy Optimization. |

| Ajinkya Technologies | Belgaum | www.ajinkyatechnologies.in | 0 - 5 Cr. | QR Code/RFID based track and trace for inventory management |

| Armtronix IoT Pvt. Ltd | Hubballi | www.armtronix.in | 0 - 5 Cr. | Machine Monitoring for: Runtime and Production Evaluation, Energy Optimization and Prediction of Failure; Quality inspection and Control using Camera; Automated Product Counting using Camera; QR Code/RFID based track and trace for inventory management |

| Arun Maisale | Belgaum | www.arunbm.online | 0 - 5 Cr. | QR Code/RFID based track and trace for inventory management; Elogbook for data capturing and visualization; Asset tracking |

| Atomwalk Technologies | Bengaluru | home.atomwalk.com | 0 - 5 Cr. | E-log book for data capturing and visualization; Machine Monitoring for Runtime and Production Evaluation; Machine Monitoring for Prediction of Failure; QR Code / RFID based track and trace for inventory management. |

| Bevywise Networks LLP | Bengaluru | www.bevywise.com | 0-5 Cr. | Elogbook for data capturing and visualization;Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Machine Monitoring for Prediction of Failure. |

| Bharat Pi | Bengaluru | www.bharatpi.net/ | 0-5 Cr. | Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Machine Monitoring for Prediction of Failure;Quality inspection and Control using Camera;Automated Product Counting using Camera;QR Code / RFID based track and trace for inventory management. |

| Bhavitha TechSolutions Pvt Ltd | Bengaluru | www.bhavithatech.com | 0-5 Cr. | Machine Monitoring for Prediction of Failure;Machine Monitoring for Runtime and Production Evaluation. |

| BizEE Technologies Private Limited | Bengaluru | www.bizee.in | 0-5 Cr. | 360 degree virtual tour of plant for better market reach. |

| Bosch | Bengaluru | www.bosch-softwaretechnologies.com/en/ | Above 1000 Cr. | Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Elogbook for data capturing and visualization;QR Code / RFID based track and trace for inventory management. |

| BuziBrAIns | Bengaluru | www.buzibrains.com | 5 - 50 Cr. | Elogbook for data capturing and visualization;Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Machine Monitoring for Prediction of Failure;Quality inspection and Control using Camera;QR Code / RFID based track and trace for inventory management;Complete Computerization of manufacturing division with AI & machine integration. |

| CAD WORLD INFOTECH | Bengaluru | www.cadworldinfotech.com | 5 - 50 Cr. | Elogbook for data capturing and visualization;360 degree virtual tour of plant for better market reach;Automated Product Counting using Camera;QR Code / RFID based track and trace for inventory management;Legacy integration, migration, Engineering and IT services. |

| E2e Rosh IT Solutions India Private limited | Bengaluru | www.e2eroshitsolutions.com | 0-5 Cr. | QR Code / RFID based track and trace for inventory management;Automated Product Counting using Camera;Quality inspection and Control using Camera. |

| Easylib Software Pvt Ltd | Bengaluru | www.easylib.net | 0-5 Cr. | QR Code / RFID based track and trace for inventory management. |

| Eoxys Systems India Pvt Ltd | Bengaluru | www.eoxys.ai | 0-5 Cr. | Machine Monitoring for Energy Optimization;Elogbook for data capturing and visualization. |

| EquiDEI | Bengaluru | NA | 0-5 Cr. | Elogbook for data capturing and visualization;Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Quality inspection and Control using Camera;Automated Product Counting using Camera. |

| eReleGo Technologies Pvt. Ltd. | Bengaluru | www.erelego.com | 5 - 50 Cr. | QR Code / RFID based track and trace for inventory management;Low code - No code technology stack compatible for any applications based on the business need. |

| Fluxgen Sustainable Technologies Private Limited | Bengaluru | www.fluxgen.com | 5 - 50 Cr. | Digital water management monitoring services. |

| Guhring India Pvt. Ltd. | Bengaluru | www.guhring.in | 50 - 100 Cr. | Machine Monitoring for Runtime and Production Evaluation;Elogbook for data capturing and visualization;Machine Monitoring for Prediction of Failure. |

| Highsecure Technologies | Bengaluru, Karnataka | www.highsecure.in | 5 - 50 Cr. | QR Code / RFID based track and trace for inventory management;Cyber Security Software Solutions,Barcode, Scanner,Touch Po's other retail softwares. |

| Ignomagine Pvt Ltd | Bengaluru | www.ignomagine.com | 0-5 Cr. | End to end automated material movement with quality check and parts counting using camera in factories and warehouses. |

| Istaffvision Consulting LLP | Bengaluru | www.istaffvision.in/ | 0-5 Cr. | Elogbook for data capturing and visualization;Quality inspection and Control using Camera. |

| iZAR Technologies | Bengaluru | NA | 50 - 100 Cr. | QR Code / RFID based track and trace for inventory management;360 degree virtual tour of plant for better market reach;Automated Product Counting using Camera;Machine Monitoring for Prediction of Failure;Machine Monitoring for Energy Optimization;Machine Monitoring for Runtime and Production Evaluation. |

| L&T Technology Services Ltd | Bengaluru | www.ltts.com | Above 1000 Cr. | Elogbook for data capturing and visualization;Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Machine Monitoring for Prediction of Failure;Automated Product Counting using Camera;360 degree virtual tour of plant for better market reach;QR Code / RFID based track and trace for inventory management;Quality inspection and Control using Camera. |

| Lidex India Pvt. Ltd. | Kozhikode | www.indeeya.in | 0-5 Cr. | Machine Monitoring for Runtime and Production Evaluation; Machine Monitoring for Prediction of Failure; Quality inspection and Control using Camera; Automated Product Counting using Camera; QR Code / RFID based track and trace for inventory management; E-log book for data capturing and visualization; Specialized in Toolroom and Component manufacturing solutions. |

| LocalView Tech Private Limited | Belagavi | vcards.localview.in | 0-5 Cr. | Machine Monitoring for Runtime and Production Evaluation; E-log book for data capturing and visualization; Machine Monitoring for Energy Optimization; QR Code / RFID based track and trace for inventory management. |

| Loginware Softtec Pvt Ltd | Bengaluru | www.loginware.ai | 0-5 Cr. | Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Machine Monitoring for Prediction of Failure;Quality inspection and Control using Camera;Automated Product Counting using Camera;QR Code / RFID based track and trace for inventory management;360 degree virtual tour of plant for better market reach;We provide the edge gateway solution (operation technology) and in information technology we have ERP, gauge management system and energy management solution which includes both hardware and software. |

| Network Friendship Media Technology Pvt Ltd | Bengaluru | NA | 0-5 Cr. | Elogbook for data capturing and visualization. |

| Perceived Design Pvt Ltd | Bengaluru | www.perceived.design | 0-5 Cr. | 360 degree virtual tour of plant for better market reach;Training and skilling platform using AR VR. |

| Presul Infotech Pvt. Ltd. | Hubballi | www.presulindia.com | 0-5 Cr. | 360 degree virtual tour of plant for better market reach; QR Code/RFID based track and trace for inventory management; Elogbook for data capturing and visualization |

| Retrack Automation Private Limited | Bengaluru | www.retrackautomation.com/ | 0-5 Cr. | Machine Monitoring for Energy Optimization. |

| Retrack Automation Pvt Ltd | Bengaluru | NA | 0-5 Cr. | Machine Monitoring for Runtime and Production Evaluation;Machine Monitoring for Energy Optimization;Machine Monitoring for Prediction of Failure;Fuel optimization & Theft Prevenion, RFID based Vehicle Authorisation. |

| Siemens | Bengaluru | NA | Above 1000 Cr. | Machine Monitoring for Runtime and Production Evaluation;QR Code / RFID based track and trace for inventory management;Elogbook for data capturing and visualization;Supply chain Traceability. |

| SiSoC engineering | Bengaluru | Www.sisocengg.com | 0-5 Cr. | Quality inspection and Control using Camera;Automated Product Counting using Camera. |

| Siddhi Analytics | Hubballi | www.siddhianalytics.com | 0-5 Cr. | Data Analytics, Report Building, Automating Data Flow |

| Sriram Systems | Bengaluru | Nill | 50 - 100 Cr. | Machine Monitoring for Energy Optimization. |

| Start IT Now | Bengaluru | Www.startitnow.co.in | 0-5 Cr. | Supply chain process automation. |

| TranZact | Mumbai | letstranzact.com/ | 5-50 Cr. | Real-time tracking of inventory and monitoring of raw materials, work-in-progress (WIP), and finished goods. |

For more details smartmanufacturing@nasscom.in or visit www.coe-iot.com